Scientists have

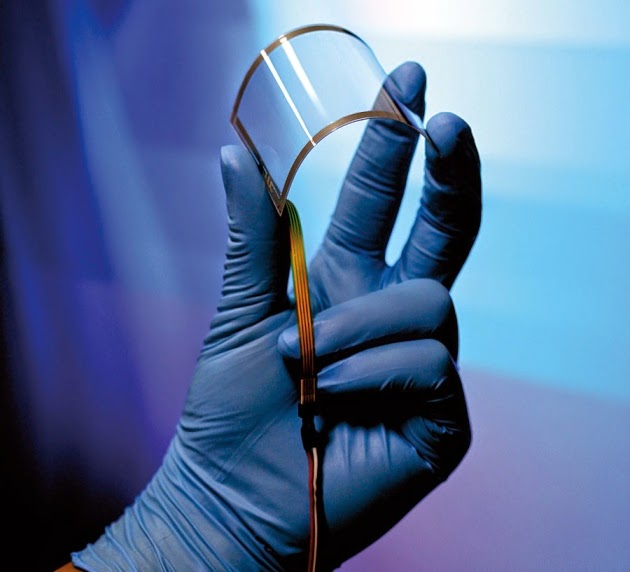

created the thinnest, lightest solar power cells yet — so lightweight that they

can be draped on top of a soap bubble without popping it.

The

researchers suggested that these ultrathin solar cells could be placed on almost any solid surface, including fabric,

paper and glass.

Solar

cells, technically known as photovoltaic cells, directly convert energy from

light into electricity.

The new solar cells are as small as 1.3 microns thick. In comparison, the

average human hair is about 100 microns thick.

The

new devices are also superlightweight, weighing only about 0.01 lbs. per square

yard (3.6 grams per square meter). In comparison, typical piece of office paper

weighs about 20 times more.

The

idea to drape a solar cell on top of a soap bubble came because "we wanted people to see how

thin this solar cell was, but you can't tell the difference between a 10-micron

and a 1-micron film by eye," said study lead author Joel Jean, an

electrical engineer at the Massachusetts Institute of Technology (MIT).

"My lab mate Patrick Brown suggested floating the cell on a bubble to make

the weight difference much more dramatic, so I tried it. My first reaction to

seeing it was probably a lot like yours — 'Cool!'"

The

new solar cells convert light to electricity with about the same efficiency as

conventional, glass-based solar cells, the researchers said. "It's unusual

for flexible cells to perform as well as rigid cells on glass," Jean told

Live Science.

In

addition, the power-to-weight ratio of the new devices is among the highest

ever achieved for solar cells. This is key to applications in which weight is

important, such as on spacecraft or on high-altitude research balloons, the researchers said.

Conventional

silicon-based solar modules produce about 6.8 watts per lb. (15 watts per

kilogram), but these new devices can generate more than 2,720 watts per lb. (6

watts per gram), or about 400 times as much.

"It

could be so light that you don't even know it's there, on your shirt or on your

notebook," study senior author Vladimir Bulović, an electrical engineer at

MIT, said in a statement. "These cells could simply be an add-on to

existing structures."

The

new cells use an organic compound known as DBP as their primary light-absorbing

material. The solar cells are sandwiched between layers of parylene, a

commercially available, flexible, transparent plastic that is widely used to

protect circuit boards and implanted biomedical devices from environmental damage.

The

solar cells and their parylene supports and coatings are fabricated in a vacuum

chamber at room temperature without the use of any solvents, the scientists

said. In contrast, conventional solar-cell manufacturing requires high

temperatures and harsh chemicals.

The

solar cells and the parylene are grown together. The parylene never needs to be

handled, cleaned or removed from the vacuum during fabrication, which minimizes

exposure to dust and other contaminants that could degrade the performance of

the solar cells, according to the researchers.

The

scientists acknowledged that the solar cell they created to sit atop a soap

bubble might be too thin to be practical — an errant breath could blow it away,

they said. "It's, of course, just for show, but we think it makes for a

good show," Jean said.

The

researchers noted they could easily fabricate parylene films up to 80 microns

thick using commercial equipment without losing the other benefits of their

manufacturing technique.

"Using

this approach, you could imagine laminating lightweight or even invisible solar

cells onto windows or other solid surfaces for building- and device-integrated

electronics," Jean said. "A more robust consumer product might use

these cells laminated onto a conventional flexible plastic sheet, which you

could carry around with you for portable power."

The

researchers noted their fabrication technique can use a variety of photovoltaic

materials beyond the ones they have demonstrated so far. "A more efficient

photovoltaic technology could reach even

higher power-to-weight ratios than the 6 watts per gram that we showed in this

first demonstration," Jean said.

The

MIT team's ultrathin solar cells are almost an order of magnitude thinner and lighter than the

previous record holder, said Max Shtein, a materials scientist at the

University of Michigan at Ann Arbor, who was not involved in this work, said in

a statement. As a result, he noted that this research "has tremendous

implications for maximizing power-to-weight [ratios] — important for aerospace

applications, for example — and for the ability to simply laminate photovoltaic

cells onto existing structures."

It's

not yet known when these solar cells might be commercially available, "but

a general rule of thumb is that it takes a decade for a technology to go from

research lab to market," Jean said. Some of the main challenges in scaling

up this approach for commercial use might include developing an integrated

system for high-throughput manufacturing — for example, roll-to-roll processing

— increasing the deposition speed, and identifying applications where an

ultralight and flexible cell would provide some unique value to the user."

Jean,

Bulović and their colleague Annie Wang, also at MIT, detailed their findings in

the April issue of the journal Organic Electronics.

.